Carros

Carros

Caminhões

Caminhões

Autocarros

Autocarros

Motociclos

Motociclos

Militar

Militar

Eletrônicos

Eletrônicos

Armas

Armas

Edifícios

Edifícios

Aeronaves

Aeronaves

Móveis

Móveis

Personagens

Personagens

Animais

Animais

Nave Espacial

Nave Espacial

Alimentação

Alimentação

Navios

Navios

mais

After numerous articles about 3D printing, which describe the breakthrough in this field, we couldn’t omit this topic as well, especially, taking into consideration our experience in 3D modeling and everyday close contact with real customers.

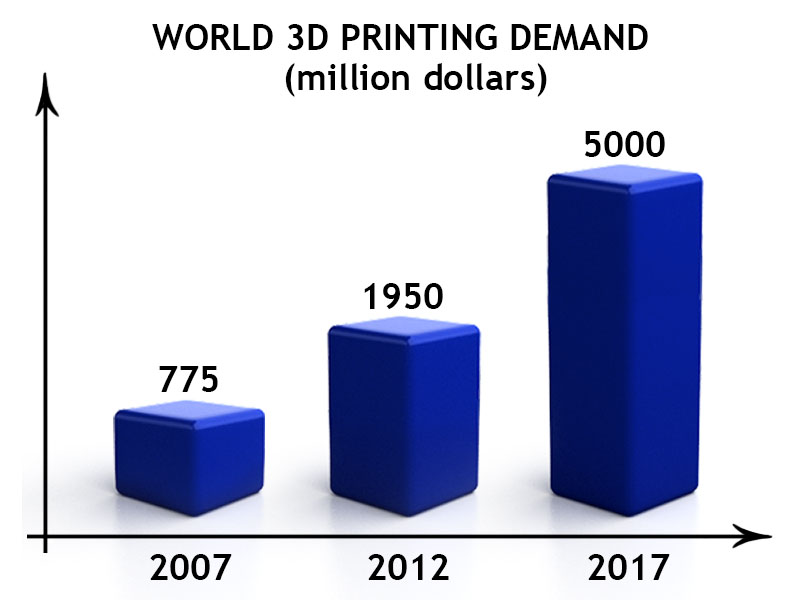

This theme has been actively discussed during the last year. Prices of 3D printers and printing costs are steadily decreasing. It is no longer a luxury, but a quite affordable device. Publications relating to this technology teem with pictures of 3D models printed on such printers together with satisfied owners both of the models and of the devices. According to some media these devices can bring danger in the society since anyone can print a real weapon from now on! This might seem just another progressive technology on rise.

Since our company is a leader in car 3D modeling and we have the largest collection of 3D cars, we automatically appear in the midst of this boom. But in practice everything turns out a little bit different comparing with how the media and press releases of 3D printer manufacturers describe it.

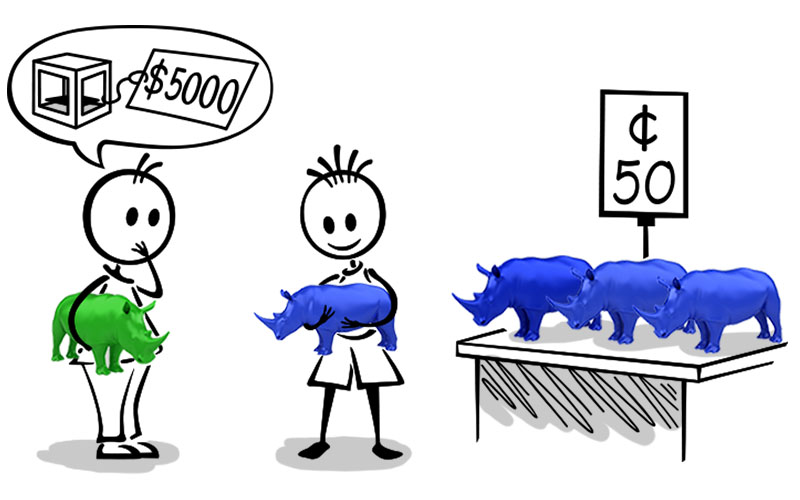

Let’s look at it through the eyes of the customer. Suppose he/she can afford to buy a 3D printer for $5000 or just print a 3D model in a company that provides 3D printing services. But what he/she can print? Free or paid 3D models which can be found in standard “test” sets for 3D printing? Is it possible that he has bought 3D printer to print the very same model that his neighbor printed a week ago? By “the very same” we understand not only the shape of the model but also its size.

As practice shows, the customer needs a very certain model. And what is more, not only a certain model, but a model of a certain size, of a certain wall thickness and with a certain level of detailed elaboration as well. Speaking from our experience in working with car 3D models, some customers want 12cm model with glass and 3mm wall thickness, while another customers can order the same model, but only 50cm size, 7mm wall thickness, without any glass but with compartment for a toy motor, batteries, etc. As you understand, different sizes of the model require different levels of detailed elaboration. And that means that it is impossible to develop a stock model for 3D printing which would satisfy all customers or at least the part of them.

It turns out that each model should be a custom order. And it’s up to five days of work or even more, depending on the complexity of the model. Therefore, the price for such model starts from $100 – $300 and can go up to $10,000 and even more. And now let’s imagine how many potential owners of 3D printers are ready to spend that money for each model? Of course, there are some. But mostly it is companies and not individual owners, who, as the matter of fact, could have as well ordered models they need and cut them on a 4-axis milling machine before.

And what about the printer that makes food for astronauts or foot prosthesis for ducks – you may say, – isn’t that an evidence that technologies from “Star Trek” is approaching? But this is exactly a specialist’s work aimed to meet specific needs. A certain duck was taken measurements, according to them a certain detail was printed and there is no need to produce it again. Moreover, the prime cost of this duck prosthesis made in the old manner can be much cheaper than the “advanced 3D Printing”.

People wouldn´t buy such expensive toys for personal use in large numbers – it all depends on the price, specialist´s going to take for the work. It’s impossible to avoid it. The question then arises as to who may need 3D Printers? Who are the potential buyers? So far, the biggest benefits of 3D printing boom are obvious only for printer manufacturers, and in no way for the broad masses. Maybe this is an empty vessel and such devices are only for specialists?

Add a comment